Engine Fuel Consumption Gauge Kit (Single flow meter)

Description

Get vital fuel information for your vehicle, boat, truck or machinery using this flow meter gauge kit. It includes a digital gauge and single flow meter for monitoring fuel supplied to the engine. You can easily monitor fuel usage, fuel flow rates and tank levels.

For orders outside of Australia email us for a freight cost.

*Prices shown in AUD.

Engine Fuel Flow & Consumption Kit

Quality precision cut gear flow meters are ideal for vehicle, machinery, generator and boat / marine engine applications. This kit will allow users to monitor fuel flowing to the engine as well as the fuel returning to the tank plus so much more.

Accurate fuel monitoring allows the operator to adjust driving behaviour to achieve significant improvements in fuel economy. Optimising your engines performance can save thousands of dollars in fuel usage. These units are especially popular due to the range based calculations it can perform. Sometimes a small change in RPM can make a massive saving to your fuel usage and efficiency.

Features:

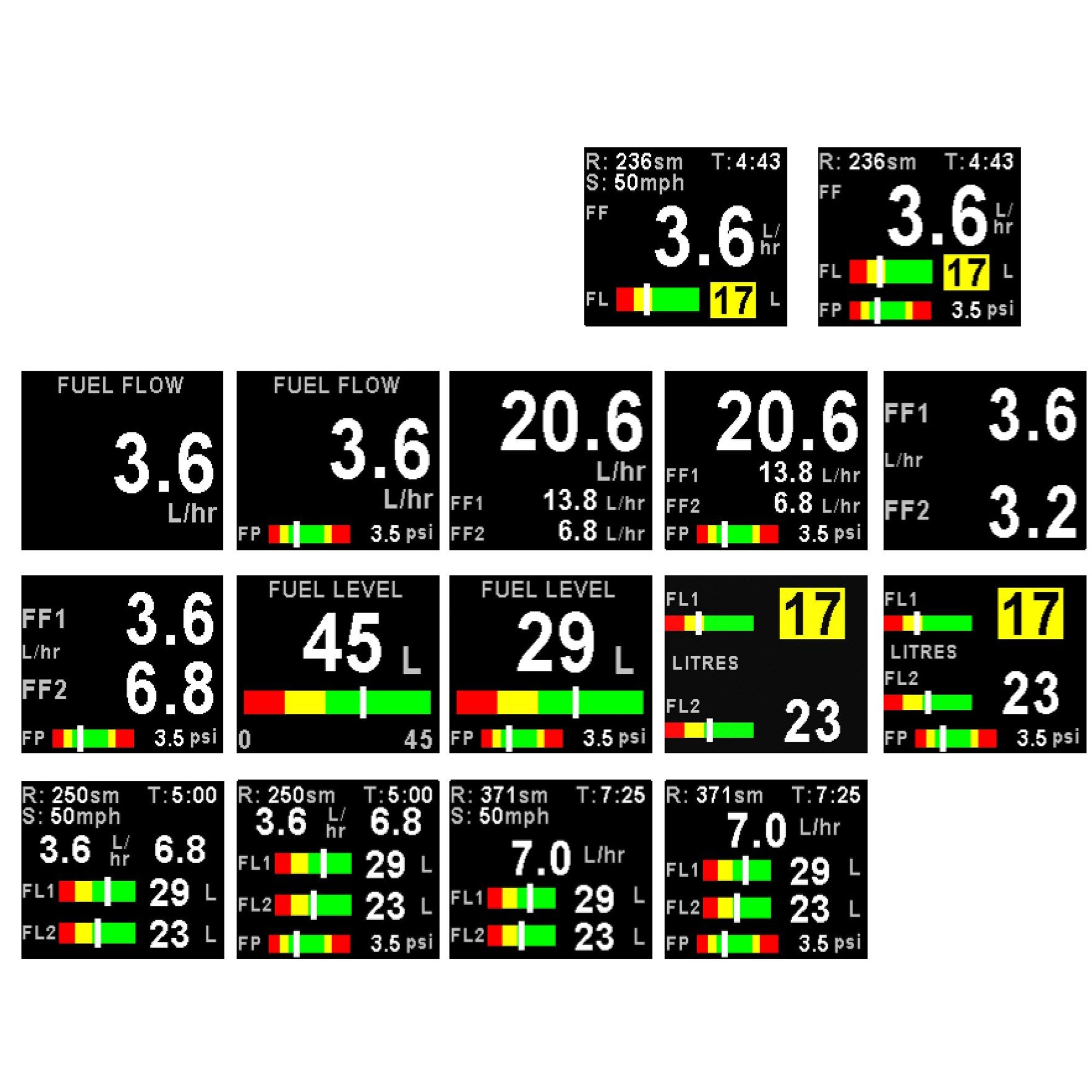

- Displays consumption in Litres per Hour (or other units)

- Has the ability to connect to a NMEA enabled RS232 GPS receiver for range based calculations

- Can export data via Marine CAN Bus (NMEA-2000) for display on compatible chart plotters

- Can display fuel remaining in up to 2 tanks when connected to sender units

- Password protection to limit access to settings and totaliser

- Highly accurate with good repeatability

- Inline flow meters are simple to retrofit to any system

- Supports single or dual fuel tanks

- Can connect to one or two fuel flow senders

- Can connect to one or two fuel level senders

- Can determine fuel consumption from fuel injectors instead of meters if desired

- Can connect to a single fuel pressure sender and display

- Comprehensive multi-point calibration system displays remaining fuel in odd shaped fuel tanks

- Output trigger when programmable alarm conditions are met warns of certain fuel conditions

- Powered by 12V - 36V power supplies

This kit has so many uses and functions users will be amazed what it can do. The primary function is to monitor fuel usage to provide a fuel consumption in L/hr. If you're running a diesel engine with a return line to the fuel tank, this kit will calculate the differential flow between the meters and calculate the consumption in L/hr.

You can also wire into your existing OEM or aftermarket fuel tank level sensor to display the fuel level in up to two tanks. If your fuel tank is odd shaped and not linear, you can perform a multipoint calibration with up to 6 points providing very accurate tank level displays. If you don't have a fuel tank sender, manually enter your fuel tank volume and let the display unit calculate the remaining fuel based on your consumption.

Enter your vehicle or crafts cruising speed and the display will calculate your range based on your instantaneous fuel consumption and remaining fuel. This input is quick and easy allowing for regular adjustments whilst underway as your cruising speed changes.

If you have a NMEA enabled RS232 GPS receiver this can be connected to display your fuel range based on your speed and remaining tank level.

If you have a NMEA 2000 compatible chart plotter, data from the SFM0000 display can be exported and displayed on plotter.

The flow meters are precision cut from steel and aluminium, no plastic gears or paddles to fail. These meters are highly accurate, repeatable and suitable for use with diesel, biodiesel, unleaded petrol and many other fuels. Flow meters should be installed downstream of a filter to ensure fuel tank debris does not jam the meters internal gears. If the gears are jammed, they are easily accessible and serviceable using a Allen Key.

The display unit is a 1.8, high resolution, sunlight readable, wide viewing angle, LCD colour display designed for flush dash mounting. The display front panel is completely sealed and waterproof and suitable for installation in open boats. The gauge enclosure is a common 52mm round size to fit many existing cutouts.

Installation of this kit is straightforward and can be completed by those with an intermediate skill level. Installers should be confident in soldering wires for the electrical side. The mechanical installation of the flow meters involves cutting existing fuel lines and installing the inline flow meters with hose clamps over the barbed fittings.

A detailed instruction manual is supplied with the kit which covers all aspects of the installation and programming of the display unit.

Kit includes:

- 1 x Flow Meters (Select your desired flow range from the drop down menu)

- 1 x Colour Display (SFM0010)

- Clamps included for kits up to 4,000 LPH.

- Instruction manual - Downloadable here

What is not included:

Hose Tail Clamps - Find them here - Hose Tail Barbs

Wiring to run between the flow meters and the display unit. Each meter has 3 wires which connect it to the head unit. One of these wires is a 12v power supply which can be shared between the meters. Additionally the earth connection to the display unit can also be shared between the meters. An electrical wiring diagram is included in the user instructions.

Fittings:We stock a limited range of fittings so in some cases you may need to source your own to suit specific requirements. Refer to the table at the bottom of this listing for the options available.

Fuel Flow Meter Specifications:

- Accuracy (standard installation position) : ±1% RS

- Maximum working pressure: 10MPa (35~85%RH)

- Low pressure drops (~2.5kPa (0.36 psi) at 100% of stated flow range)

- Fluid & Ambient temperature: -40 to 80°C

- Pulse unit : 0.661 ml/p (~1513 P/L - note each meter is calibrated and provided with pulse count/L)

- Power voltage: 3 - 24V DC

- Output signal: NPN Open collector

- Rotor and casing: Aluminium anodize

- O-ring: NBR

- Shaft: Stainless Steel

- Compatible fluids: kerosene, Gasoline, unleaded petrol, diesel, biodiesel, light oil, heavy oil

- Warranty: 12 months

- CE Certificate & Calibration Certificate can be supplied on request at an additional cost.

| Flow Range | Inlet / Outlet Port Size |

|---|---|

| 0.5 - 60 LPH | 1/4" BSP Female |

| 5 - 150 LPH | 1/4" BSP Female |

| 20 - 300 LPH | 3/8" BSP Female |

| 50 - 800 LPH | 1/2" BSP Female |

| 200 - 4,000 LPH | 1" BSP Female |

| 500 - 10,000 LPH | 1-1/2" BSP Female |

A Guide to Selecting the Correct Kit

Note, the following is a guide only. We strongly suggest you seek the advice of your engine manufacture when selecting the most suitable sized flow meters for your engine. We do not take responsibility if you select the wrong size kit although we will work with you to rectify.

Diesel Engines - Diesel engines typically have a fuel supply line to the engine and a fuel return line to the tank. Whilst rare, some designs do loop the fuel return to the supply line, meaning you will only require a single flow meter in the common line from the tank.

Fuel is typically supplied to the engine in excess to what is actually consumed and this is required to ensure the engine is not starved during peak demands, it also allows the fuel system to circulate and stay cool. Some engine manufactures report 50-85% of the supplied fuel to the engine is returned to the tank.

With the above in mind, let's consider a 200hp diesel engine which might be known to consume ~30L/hr at full RPM and ~10L/hr at idle. If we assume ~70% of the fuel sent to the engine is returned to the tank we can calculate the approximate flows in the supply and return line at different conditions.

30L/hr / 30% = 100L/hr to the engine normally.

100L/hr - 30L/hr = 70 L/hr returning to the tank at full RPM.

100L/hr - 10L/hr = 90 L/hr returning to the tank at idle.

For the above scenario one could consider flow meters which are ranged for flows between 5-150 L/hr or 20-300 L/hr as most suitable.

Users should query their engine manufacture for the fuel flow to the engine vs flow returning to the tank at idle and full load to be certain in their selection.

Petrol Engines - Petrol engines typically don't have a fuel return line back to the tank. Therefore selecting a flow range should be based on users understanding of fuel consumed at idle vs full load. Using the same example above, a 200 hp petrol engine might be estimated to burn 10 L/hr at idle and 160 L/hr at full load. In this scenario one could consider the 20-300 L/hr range noting the accuracy of the meter when idling may not meet the tabulated 1% RS.

Guide for Maximum / Minimum Hose Tail Sizes

Scintex can supply the following hose tail fittings sizes for each flow meter. The ports are female BSP threaded and can accept many types of fittings if you wish to source your own. Each flow meter is supplied with 2 fittings, 1 for the inlet and 1 for the outlet. Fittings up to 1" are included in the price. For larger fittings contact us for a quote.

| Flow Meter | Minimum Hose Tail | Maximum Hose tail |

|---|---|---|

| 0.5-60LPH | 1/4" Hose Tail | 1/2" Hose Tail |

| 5-150LPH | 1/4" Hose Tail | 1/2" Hose Tail |

| 20-300LPH | 3/8" Hose Tail | 1/2" Hose Tail |

| 50-800LPH | 1/2" Hose Tail | 3/4" Hose Tail |

| 200-4,000LPH | 3/4" Hose Tail | 1 1/4" Hose Tail |

| 500-10,000LPH | 1" Hose Tail | 2" Hose Tail |